A légiközlekedés hatékonyságának fejlesztése az európai légtérben

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iSGtWYXFjSUtJQ2s/view?usp=sharing

[Did you know?]

Glasgow Prestwick Airport is considered to be the only place in the United Kingdom where Elvis Presley ever set foot, when the United States Army transport plane carrying him home stopped to refuel in 1960, en route from Germany. A lounge bearing his name and a marker reflecting this event were inaugurated in 2006.

100 Years of Commercial Aviation

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iLXNrTWRMWHZHSFE/view?usp=sharing

Transporting a symbolic flame on-board

Extract from the 54th edition of Dangerous Goods Regulations, 2013:

5.0.1.10 Carriage of Flames

With the approval of the appropriate authority of the State of Origin, or transit (where applicable), of Destination and of the Operator, lamps fuelled by UN 1223--Kerosene or UN 3295-- Hydrocarbons, liquid, n.o.s., carried by a passenger to transport a symbolic flame (e.g. Olympic flame, Peace flame) may be carried in accordance with the provisions of Special Provision A224.

A224

For the purpose of transporting a symbolic flame, the appropriate authority of the States of origin, of destination and of the operator may appropve the carriage of lamps fuelled by UN 1223--Kerosene, or UN 3295--Hydrocarbons, liquid n.o.s., carried by a passenger as carry on baggage only.

Lamps must be of a "Davy" type or similar apparatus. In addition, the following conditions apply as a minimum:

a) no more than four lamps may be carried on board the aircraft;

b) lamps may contain no more fuel than the quantity adequate for the duration of the flight and the fuel must be contained in a leakproof reservoir;

c) lamps must be adequately secured;

d) whilst on board the aircraft, the lamps must be under the constant supervision of an accompanying person, who must not be a member of the operating crew;

e) lamps may be lit by the accompanying person, but must not be refilled on board the aircraft;

f) at least one fire extinguisher must be kept within reach of the accompanying person at all times. The accompanying person must be trained in the use of the extinguisher.;

g) the crew members of the aircraft must be given a verbal briefing about the carriage of the lamps and the pilot-in-command must be provided with a copy of the approval; and

h) 9.5.1.1.1b), c), e), 9.5.1.2, 9.5.1.3 and 9.6.1 of these Regulations must apply.

[Did you know?]

- The Olympic flame went airborne for the first time on the Helsinki 1952 Summer Olympics, flying to the Danish city of

Aalborg following an initial journey between Olympia and Athens. After making its way across Denmark and into

Sweden, it passed through Gothenburg and Stockholm and then crossed the Finnish border at Tornio. From there it

was borne to Tampere and on to Helsinki, the final destination of a 7,492 km journey.

- For the 1992 Winter Olympics in Albertville, France, the torch flew from Athens to Paris on board of a Concorde.

Source:

https://www.olympic.org/news/the-amazing-story-of-the-olympic-flame

Dangerous Goods Regulations

54th Edition, effective only till 31 Dec 2013

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iZkltWDdnRVhYbGc/view?usp=sharing

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iZkltWDdnRVhYbGc/view?usp=sharing

[Final report] MP 495

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iSjBwdFVpRXhHLWs/view?usp=sharing

Flight Crew of DC-10 Encounters Microburst During Unstabilized Approach, Ending in Runway Accident

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iMkt3OXdNdE9hQzA/view?usp=sharing

An Analysis of McDonnell Douglas’s Ethical Responsibility in the Crash of Turkish Airlines Flight 981

Download it:

https://drive.google.com/file/d/0B8aiechh7K6ickQwV1NzWnBnbXc/view?usp=sharing

[Final report] TK 981

Download it:

https://drive.google.com/file/d/0B8aiechh7K6ic21pUURxREpUVFU/view?usp=sharing

TK 981

|

| Complete destruction in the Ermenonville forest |

The crash was caused when an improperly secured cargo door at the rear of the plane broke off, causing an explosive decompression which severed cables necessary to control the aircraft. Because of a known design flaw left uncorrected before and after the production of DC-10s, the cargo hatches did not latch reliably, and manual procedures were relied upon to ensure they were locked correctly. Problems with the hatches had occurred previously, most notably in an identical incident that happened on American Airlines Flight 96 in 1972. Investigation showed that the handles on the hatches could be improperly forced shut without the latching pins locking in place. It was noted that the pins on the hatch that failed on Flight 981 had been filed down to make it easier to close the door, resulting in the hatch being less resistant to pressure. Also, a support plate for the handle linkage had not been installed, although manufacturer documents showed this work as completed. Finally, the latching had been performed by a baggage handler who did not speak Turkish or English, the only languages provided on a warning notice about the cargo door's design flaws and the methods of compensating for them. After the disaster, the latches were redesigned and the locking system significantly upgraded.

Aircraft

|

| McDonnell-Douglas DC-10-10 'Ankara' |

Accident

Flight 981 had flown from Istanbul that morning, landing at Paris's Orly International Airport just after 11:00 am local time. The aircraft was carrying just 167 passengers and 11 crew members in its first leg. 50 passengers disembarked in Paris. The flight's second leg, from Paris to London Heathrow Airport, was normally underbooked, but due to strike action by British European Airways employees, many London-bound travellers who had been stranded at Orly were booked onto Flight 981. 216 new passengers boarded the flight. As a result, the layover

increased from the normal one hour to one hour and thirty minutes. Among them were 17 English rugby players who had attended a France–England match the previous day; the flight also carried six British fashion models, and 48 Japanese bank management trainees on their way to England, as well as passengers from a dozen other countries.

The aircraft left Orly at 12:32 pm, bound for Heathrow. It took off in an easterly direction, then turned to the north to avoid flying directly over Paris. Shortly after the take off, Flight 981 was cleared to FL230 (23,000 ft.), and started turning to the west, towards London. Shortly after 12:40 pm, just after Flight 981 passed over the town of Meaux, the rear left cargo door blew off. The sudden difference between the air pressure in the cargo area and the pressurised passenger cabin above it, which amounted to 2 pounds per square inch or 14 kilopascals, caused a section of the cabin floor above the open hatch to fail and blow out through the hatch, along with six occupied passenger seats attached to the floor section. The fully recognizable bodies of the six passengers who were ejected from the aircraft were found along with the plane's rear hatch, all having landed in a turnip field near Saint-Pathus, approximately 15 kilometres (9.3 miles) south of where the remainder of the plane would crash. An air traffic controller noted that as the flight was cleared to FL230, he had briefly seen a second echo on his radar, remaining stationary behind the aircraft, likely the remains of the rear cargo door.

When the door blew off, the primary as well as both sets of backup control cables that ran beneath the section of floor that was blown out were completely severed. This resulted in the pilots losing the ability to control the plane's elevators, rudder, and Number 2 and 3 engines. The flight data recorder showed that the throttle for Engine 2 snapped shut when the door failed. The loss of control of these key components meant that the pilots lost control of the aircraft entirely.

|

| "...disintegrated into millions of pieces instantly" |

Investigation

The French Minister of Transport appointed a commission of inquiry by the Arrêté 4 March 1974. Because the aircraft was manufactured by an American company, observers from the United States participated. There were many passengers on board from Japan and the United Kingdom, so observers from those countries followed the investigation.

Lloyd's of London insurance syndicate, which covered Douglas Aircraft, retained Failure Analysis Associates (now Exponent, Inc.) to investigate the accident as well. In the company's investigation, Dr. Alan Tetelman noted that the pins on the cargo door had been filed down. He learned that on a stop in Turkey, the ground crews had trouble closing the door. They filed the pins down, reducing them by less than a quarter of an inch (6.4 millimetres), and were then able to close the door effortlessly. It was proven by tests that the door subsequently yielded to about 15 psi (100 kPa) of pressure, in contrast to the 300 psi (2,100 kPa) that it had been designed to withstand.

Cause

|

| Recovered cargo door during the technical examination |

To ensure this rotation was complete and the latches were in the proper position, the DC-10 cargo hatch design included a separate locking mechanism that consisted of small locking pins that slid behind flanges on the lock torque tube (which transferred the actuator force to the latch hooks through a linkage). When the locking pins were in place, any rotation of the latches would cause the torque tube flanges to contact the locking pins, making further rotation impossible. The pins were pushed into place by an operating handle on the outside of the hatch. If the latches were not properly closed, the pins would strike the torque tube flanges and the handle would remain open, visually indicating a problem. Additionally, the handle moved a metal plug into a vent cut in the outer hatch panel. If the vent was not plugged, the fuselage would not retain pressure, eliminating any pneumatic force on the hatch. Also, there was an indicator light in the cockpit, controlled by a switch actuated by the locking pin mechanism, that remained lit unless the cargo hatch was correctly latched.

Similarities American Airlines Flight 96

|

| Cargo door of Flight 96 being observed after landing |

In the aftermath of Flight 96, the NTSB made several recommendations. Its primary concern was the addition of venting in the rear cabin floor that would ensure that a cargo area decompression would equalise the cabin area, and not place additional loads onto the floor. In fact, most of the DC-10 fuselage had vents like these; only the rearmost hold lacked them. Additionally, the NTSB suggested that upgrades to the locking mechanism and to the latching actuator electrical system be made compulsory. However, while the FAA agreed that the locking and electrical systems should be upgraded, it also agreed with McDonnell-Douglas that the additional venting would be too expensive to implement, and did not demand that this change be made.

The plane that crashed as Flight 981, TC-JAV, or "Ship 29", had been ordered from McDonnell-Douglas three months after the service bulletin was issued, and was delivered to Turkish Airlines another three months after that. Despite this, the changes required by the service bulletin (installation of a support plate for the handle linkage, preventing the bending of the linkage seen in the Flight 96 incident) had not been implemented. The interconnecting linkage between the lock and the latch hooks had not been upgraded. Through either oversight or deliberate fraud, the manufacturer construction logs nevertheless showed that this work had been carried out. An improper adjustment had been made to the locking pin and warning light mechanism, however, causing the locking pin travel to be reduced. This meant that the pins did not extend past the torque tube flanges, allowing the handle to be closed without excessive force (estimated by investigators to be around 50 pounds-force or 220 newtons) despite the improperly engaged latches. These findings concurred with statements made by Mohammed Mahmoudi, the baggage handler who had closed the door on Flight 981; he noted that no particular amount of force was needed to close the locking handle. Changes had also been made to the warning light switch, so that it would turn off the cockpit warning light even if the handle was not fully closed.

|

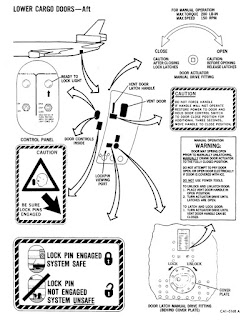

| Aft cargo door placards on a DC-10 |

It was normally the duty of either the airliner's flight engineer or the chief ground engineer of Turkish Airlines to ensure that all cargo and passenger doors were securely closed before takeoff. In this case, the airline did not have a ground engineer on duty at the time of the accident, and the flight engineer for Flight 981 failed to check the door personally. Although French media outlets called for Mahmoudi to be arrested, the crash investigators stated that it was unrealistic to expect an untrained, low-paid baggage handler who could not read the warning sticker to be responsible for the safety of the aircraft.

Aftermath

The latch of the DC-10 is a study in human factors, interface design, and engineering responsibility. The control cables for the rear control surfaces of the DC-10 were routed under the floor. Therefore, a failure of the hatch that resulted in a collapse of the floor could impair the controls. If the hatch were to fail for any reason, there was a very high probability the plane would be lost. To make matters worse, Douglas chose a new type of latch to seal the cargo hatch. This possibility of a catastrophic failure as a result of this overall design was first discovered in 1969, and actually occurred in 1970 in a ground test. Nevertheless, nothing was done to change the design, presumably because the cost for any such changes would have been borne as out-of-pocket expenses by the fuselage's subcontractor, Convair. Although Convair informed McDonnell Douglas of the potential problem, Douglas ignored these concerns, because rectification of what Douglas considered to be a small problem with a low probability of occurrence would have seriously disrupted the delivery schedule of the aircraft, and caused Douglas to lose sales. Dan Applegate was Director of Product Engineering at Convair at the time. His serious reservations about the integrity of the DC-10's cargo latching mechanism are a classic case in engineering ethics.

After the crash of Flight 981, the latching system was completely redesigned. The latches were redesigned to prevent them from moving into the wrong positions in the first place. The locking system was mechanically upgraded to prevent the handle from being forced closed without the pins in place, and the vent door was altered to be operated by the pins, thereby indicating when the pins, rather than the handle, were in the locked position. Additionally, the FAA ordered further changes to all aircraft with outward-opening doors, including the DC-10, Lockheed L-1011, and Boeing 747, requiring that vents be cut into the cabin floor to allow pressures to equalise in the event of a blown-out door.

Similar accidents

An outward-opening cargo hatch is inherently less resistant to blowing open than an inward-opening one, also called a plug door. In flight, the air pressure inside the aircraft is greater than that outside, and pushes outward on the hatch. In the case of a plug door, this actually seals the door more tightly. An outward-opening hatch, however, relies entirely upon its latch to prevent it from opening in flight. This makes it particularly important that the locking mechanisms be secure. Aircraft other than DC-10s have also experienced catastrophic failures of hatches. The Boeing 747 has experienced several such incidents, the most noteworthy of which occurred on United Airlines Flight 811 in February 1989. On Flight 811, the cargo hatch failed, causing a section of the fuselage to fail, resulting in the deaths of nine passengers, who were blown out of the aircraft.

The NTSB's recommendations following the earlier Flight 96 incident, which were intended to decrease the possibility of another hatch failure, were not implemented by any airline. As a result, the NTSB now communicates directly with the FAA regarding the former's recommendations for safety improvements, and the FAA may issue Airworthiness Directives based on those recommendations. However, the FAA is not obligated to act on NTSB recommendations.

Source:

https://en.wikipedia.org/wiki/Turkish_Airlines_Flight_981

Turkish Flight 981 and American Airlines Flight 96

Flight 981 and American Airlines Flight 96 were examined in "Behind Closed Doors", an episode from the fifth season of the Canadian National Geographic Channel series Mayday (US series title: Air Disasters; international title: Air Crash Investigation).

Case Study: the Charkhi Dadri Mid-Air Collision

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iU1M4T2o4bDZWUUk/view?usp=sharing

[Final report] Britannia Airways Flight 226A

Download it (report + appendices):

https://drive.google.com/file/d/0B8aiechh7K6iaURtVHQ2Yy1sY1U/view?usp=sharing

BY 226A

|

| G-BYAG beyond economic repair... |

Flight history

The holiday charter flight was landing at night, through thunderstorms with heavy rain at 21:47 UTC (23:47 local). Several preceding flights had diverted to Barcelona and this was planned as BY226A's alternate. The weather prior to the landing approach was reported as:

Surface wind 350/6 kt, visibility 4 km, thunderstorm with heavy rain, cloud 3–4 octas at 1,500 feet, 1–2 octas cumulonimbus at 3,000 feet, 5–7 octas at 4,000 feet, temperature 20 °C/ dewpoint 20 °C, QNH 1010 mb, remarks recent rain.

Accident sequence

The crew initially executed the VOR/DME non-precision instrument approach procedure to runway 02. Upon becoming visual, the crew determined that the aircraft was not adequately aligned with the runway and initiated a missed approach. A change in wind direction now favoured the opposite runway, so the aircraft was positioned for an ILS (Instrument Landing System) approach to runway 20. The aircraft descended below cloud and became visual with the runway at around 500 feet (150 m) above ground level. At a late stage in the final approach, the airfield lighting failed for a few seconds. The aircraft touched down hard, bounced, and made a second heavier touchdown causing substantial damage to the nosewheel and its supports. This caused further damage to the aircraft systems, including loss of electrical power, interference with controls and an uncommanded increase in thrust.

|

| Scene beyond the airport perimeter fence |

Damage was substantial: the fuselage was fractured in two places and the landing gear and both engines detached. Despite considerable damage to the cabin, the crew evacuated the aircraft efficiently. However, 3 of the 8 emergency exits could not be opened and several escape slides did not inflate (though with the fuselage sitting on the ground this was not a great problem).

|

| Hard to find if you don't know where to search for it |

Post-crash

There were no immediate fatalities and the injuries were few: 2 serious and 42 minor. However, one passenger, who had been admitted to hospital with apparently minor injuries and discharged the following day, died five days later from unsuspected internal injuries.

Airport authorities were criticised after the accident, particularly for the fact it took rescue crews more than an hour to reach and evacuate the scene. Indeed, at least one passenger actually walked across the airfield to the terminal to seek help.

Investigation and final report

The accident was investigated by the Spanish Civil Aviation Accident and Incident Investigation Commission (CIAIAC). In its final report, the CIAIAC's finding was:

"It is considered that the most probable cause of the accident was the destabilisation of the approach below decision height with loss of external visual references and automatic height callouts immediately before landing, resulting in touchdown with excessive descent rate in a nose down attitude. The resulting displacement of the nose landing gear support structure caused disruption to aircraft systems that led to uncommanded forward thrust increase and other effects that severely aggravated the consequences of the initial event."The following contributing factors were also determined:

- Impairment of the runway visual environment as a result of darkness and torrential rain and the extinguishing of runway lights immediately before landing.

- Suppression of some automatic height callouts by the GPWS "SINK RATE" audio caution.

- The effect of shock or mental incapacitation on the PF (Pilot Flying) at the failure of the runway lights which may have inhibited him from making a decision to go-around.

- The absence of specific flight crew training in flight simulators to initiate a go-around when below landing decision height.

- Insufficient evaluation of the weather conditions, particularly the movement and severity of the storm affecting the destination airport."

Source:

https://en.wikipedia.org/wiki/Britannia_Airways_Flight_226A

[Grasshoppair presents...] Sunrise landing at Corfu

Approach and landing RWY35..

Wizzair A321 low-pass over the River Danube

On 1 May 2016, our Airbus A321 aircraft flew low above the Danube in the historical centre of Budapest as part of the Nagy Futam air show. This wouldn’t have been possible without the excellent expertise of Chief Flight Operations Officer Captain David Morgan and Captain András Arday, who performed 3 breath-taking flights above the Danube!

The uniform-freak

Cliff Muskiet, purser for KLM, has collected 1308 different uniforms issued by 483 airlines...

...some of them displayed at some distinctive Schiphol locations:

...some of them displayed at some distinctive Schiphol locations:

[Grasshoppair presents...] Stunning approach to Kos

Our landing on beautiful Kos island's RWY32.. :)

[Jobs at close from Malpensa] Bird Control Unit

Working at the airport to prevent the risk of collisions between wildlife and aircrafts. The Bird Control Unit is a wildlife control unit in charge of reducing the risk of collisions between wildlife and aircrafts. To deter animals and thus avoid impacts, they use acoustic dispersal systems.

[Jobs at close from Malpensa] The police dog

Some of the most important workers have tails! Kira and her fellow police dog have a very special job, helping police in protect the airport. They have strong and important relationship, in order to get the best from every operation!

[Jobs at close from Malpensa] Passengers with Reduced Mobility

A free service dedicated to travelers with reduced mobility, a profession close to passengers and their needs. Sala Amica is a comprehensive service for passengers with reduced mobility offered free of charge from the airports of Milano Linate and Malpensa .

Qualified airport staff welcomes those passengers who require the service and offer them complete assistance throughout the boarding process (check in, security control and boarding).

At any time the passengers may stop at the Sala Amica lounges available in the airport or use other airport services.

If you have a disability or are a passenger with reduced mobility submit a request for assistance to the airline at least 48 hours before departure.

[Jobs at close from Malpensa] The baggage handling system

When you travel, your luggage are flying with you! But how is their trip going, once you’ve left them at the check in desk? The baggage themselves are showing you, thanks to special camera who will follow every movement!

[Jobs at close from Malpensa] The Air Traffic Controller

The journey to discover Malpensa airport continues. Today, in the fifth episode of "10 People Tell Their Stories", Daniele, air traffic controller at ENAV Control Tower, tells us more about his job and how an airport control tower works.

[Jobs at close from Malpensa] The De-icer

How do you remove ice from an airplane? De-Icing! It’s a treatment coney when the aircrafts are contaminated with the presence of ice and frost, and it is requested by the captain himself.

The treatment is done washing the aircraft with high temperature water and with a specific liquid called Kilfrost, used to protect the aircraft. It’s a must do operation, because it has to do with the safety of airplanes and passengers, and you cannot do any mistake.

[Jobs at close from Malpensa] The Ramp Agent

What does a ramp agent do? No one knows better about the correct preparation of cargo and aircraft. Andrea, the first featured in our series “10 People Tell Their Stories”, introduces us to one of the most fascinating professions at the airport!The ramp agent is in charge of all ground handling operations for the aircraft’s stop and turn-around process. His job is to check every activity that takes place with the aircraft: passengers disembarkation, unloading of baggage, cargo, mail, refuelling and maintenance. He also coordinates catering operations, aircraft cleaning, loading of the aircraft itself as well as passenger boarding: the plane is prepared for the next flight, day and night. That’s because Malpensa is an intercontinental airport, open 24/7 for cargo and freight traffic.

Andrea talks of cargo, amusing anecdotes and marshalling ... curious to know what it is?

Station Capability List

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iLUthSTIzVFItNFk/view?usp=sharing

Line Maintenance Services Price List

International station only!

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iUjE4QWFZQW90Z1E/view?usp=sharing

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iUjE4QWFZQW90Z1E/view?usp=sharing

Line Maintenance Services Price List

German stations only!

Download it:

https://drive.google.com/file/d/0B8aiechh7K6icnA4VjVCZWhDRHM/view?usp=sharing

Download it:

https://drive.google.com/file/d/0B8aiechh7K6icnA4VjVCZWhDRHM/view?usp=sharing

Dynamic Cost Indexing

Download it:

https://drive.google.com/file/d/0B8aiechh7K6icnFOejRRQzlsUHc/view?usp=sharing

Human Factors

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iR194RURFSkU3aTQ/view?usp=sharing

An Overview Of Human Factors in Aviation Maintenance

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iWHM2dndENnFKYlE/view?usp=sharing

Inspection Fundamentals

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iaVV5RjBfUVFTRVU/view?usp=sharing

[Grasshoppair bemutatja...] Cloudy welcome at Innsbruck

Leszállásunk a 08-as pályára.. :)

Felszállás:

https://www.youtube.com/watch?v=jynwLt2DPFY

Felszállás:

https://www.youtube.com/watch?v=jynwLt2DPFY

[Tech acronyms] AOG

Aircraft on Ground or AOG is a term in aviation maintenance indicating that a problem is serious enough to prevent an aircraft from flying. Generally there is a rush to acquire the parts to put the aircraft (A/C) back into service, and prevent further delays or cancellations of the planned itinerary. AOG applies to any aviation materials or spare parts that are needed immediately for an aircraft to return to service. AOG suppliers refer qualified personnel and dispatch the parts required to repair the aircraft for an immediate return to service. AOG also is used to describe critical shipments for parts or materials for aircraft "out of service" or OTS at a location.

Aircraft on Ground or AOG is a term in aviation maintenance indicating that a problem is serious enough to prevent an aircraft from flying. Generally there is a rush to acquire the parts to put the aircraft (A/C) back into service, and prevent further delays or cancellations of the planned itinerary. AOG applies to any aviation materials or spare parts that are needed immediately for an aircraft to return to service. AOG suppliers refer qualified personnel and dispatch the parts required to repair the aircraft for an immediate return to service. AOG also is used to describe critical shipments for parts or materials for aircraft "out of service" or OTS at a location.

Mitigation of AOG status: When an aircraft "goes AOG" and materials required are not on hand, parts and personnel must be driven, flown, or sailed to the location of the "grounded A/C". Usually the problem is escalated through an internal AOG Desk, then the Manufacturer's AOG Desk, and finally competitors' AOG desks. All major air carriers have an "'AOG Desk". This desk is manned 24/7 by personnel trained in purchasing, hazardous materials shipping, and parts manufacturing / acquisition processes.

AOG personnel are trained to "loan" or "borrow" spare parts from other air carriers, per FAA/EASA etc. regulations. AOG personnel work in conjunction with their carriers' maintenance operations department, supporting aircraft maintenance with all parts or material requests very rapidly. There are two ways of achieving this: by local engineering support or by support flown out base.

Source:

https://en.wikipedia.org/wiki/Aircraft_on_ground

Source:

https://en.wikipedia.org/wiki/Aircraft_on_ground

747 “D” Inspection

One 747-200 had accumulated 36,000 hours in eight years when it hit the hangar for a “heavy” checkup, also called a “D” inspection. The big D is a really big deal that can take up to a month or more and cost upwards of $2 million. See what it takes for this Boeing behemoth to get a clean bill of health.

What Does It Take To Keep Them Flying?

Ladies and gentlemen, welcome to New York City's John F. Kennedy Internation al Airport." That announcement to arriving passengers marks the beginning of a flurry of activity in and around the aircraft as its occupants leave. Have you ever wondered what happens to the plane at this point?

Commercial aircraft make money only while flying passengers or cargo, not while sitting on the ground. Therefore, airlines aim for the highest possible utilization of their fleets. As passengers wait for their baggage, the aircraft is being swiftly prepared for the next flight. Mechanics swing into action by reviewing the aircraft log for any mechanical problems noted by the last flight crew. Any matters affecting the safe operation of the plane, also called nogo items, are corrected.

The aircraft's wheels, tires, brakes, and engine oil levels are checked. Cleaning crews tidy up the passenger cabin. The kitchen units, or galleys, are resupplied with food and beverages. Fuel is pumped into the wing tanks. Before the aircraft is again ready for departure, the flight crew performs an exterior walkaround inspection, checking for any conditions that might compromise safety.

This turnaround service and immediate maintenance is performed on thousands of aircraft every day. But that is only a tiny fraction of what it takes to keep a large passenger plane safe to fly. Just as automobiles need periodic servicing, airplanes regularly require a series of extensive and expensive maintenance checks. Who perform these aircraft maintenance services? How is the work carried out?

How the Planes Are Kept Airworthy

According to the U.S. Air Transport Association, member airlines carry more than 95 percent of the air traffic, both passenger and freight, in the United States. In 1997 those airlines had about 65,500 aircraft mechanics on the job. Along with engineers and other maintenance personnel, the aircraft mechanics' mission is to keep the aircraft airworthy and to ensure passenger comfort. That means inspecting, repairing, and overhauling the multitude of specialized parts —the machines within the machine—that make an airplane fly.* Such scheduled maintenance includes everything from overhauling jet engines weighing over four tons to replacing wornout cabin carpets.

* A 747-400 has six million parts, half of which are fasteners (rivets and bolts), and 171 miles of electrical wiring.

Most mechanical problems get immediate attention. However, the aircraft maintenance program schedules other maintenance on the basis of the number of months the aircraft has been in use or the number of cycles # and the number of hours each aircraft has flown, not on the total number of miles it has flown. The program begins with maintenance recommendations made by the aircraft manufacturer to the airplane operators, which must be acceptable to government aviation authorities. Each aircraft has its own tailored maintenance program, from light to intermediate to heavy checks. These checks are designated by letters, such as A, B, C, D, L, or Q.

# A cycle equals one take-off and landing

One 747-200 took about eight years to accumulate some 36,000 hours of flying time. When it did, it was time to head to the hangar for a heavy check, sometimes called a D check. Commenting on this complex and time consuming check, Overhaul & Maintenance, an aviation management magazine, says: "The goal . . . is to, as much as possible, return an entire airframe to its original condition… A D check takes between 15,000 and 35,000 hrs. of labor, and can put a plane out of service for 15 to 30 days, or more. The total cost averages between $1 million and $2 million." "A typical D check is 70% labor and 30% material" said Hal Chrisman of The Canaan Group, an aerospace management consulting firm. Of course, some of that cost is included in your airline ticket.

What a D Check Involves

Once the aircraft is parked inside the hangar—a huge complex of aircraft service areas, support shops, and warehouses—the maintenance team goes to work. Worktables, platforms, and scaffolds are rolled into position for access to otherwise unreachable areas of the plane. Seats, floors, walls, ceiling panels, galleys, lavatories, and other equipment are opened or removed from the aircraft to permit close inspection. The aircraft is essentially gutted. Following step-by-step instructions, workers examine the aircraft for signs of metal cracks and corrosion. Whole sections of the aircraft’s landing gear, hydraulic system, and engines may be replaced. The D check requires the skills of engineers, technical writers, quality control inspectors, avionics technicians, * sheet-metal workers, and airframe and power-plant mechanics, ** most of whom are government licensed. When cabin equipment mechanics, painters, and cleaners are added, the number of personnel swells to well over 100 per day. Scores of others provide essential equipment, parts, and logistics support.

* “Avionics” is an abbreviation for aviation electronics.

**The airframe and power-plant certificate allows mechanics to approve flight work that he or she has performed on airplane structures, systems and engines.

Over time, inflight vibrations, fuselage pressurization cycles, and the jolts of thousands of takeoffs and landings cause cracks in the metal structure of the aircraft. To address this problem, aviation employs diagnostic principles similar to those used in the field of medicine. Both use such tools as radiology, ultrasonics, and endoscopy to detect what the human eye cannot see.

For a conventional medical X ray, the patient is placed between a sheet of film and an Xray beam. To Xray the landing gear, wings, and engines, maintenance inspectors use similar methods. For example, a sheet of Xray film is placed at a desired point on the engine exterior. Next, a long metal tube is placed inside the hollow shaft that runs the length of the engine. Finally, a pill of radioactive iridium 192—a powerful isotope—no bigger than a pencil eraser, is cranked into the tube to expose the Xray film. The developed film helps to reveal cracks and other flaws that may require that the engine be repaired or replaced.

During the D check, samples of the aircraft's fuel and its hydraulic fluids are sent for laboratory analysis. If microorganisms are found in the fuel sample, antibiotics are prescribed. To kill jet fuel bugs—fungi and bacteria that can get into fuel tanks through the air, water, and fuel—the tanks are treated with a biocide, a form of antibiotic. This treatment is important because the byproducts of microbial growth can corrode the protective coatings on the surface of the tanks. Fuel probes in the tanks can also be affected and thus cause the pilots to receive inaccurate fuel gauge readings.

As a result of normal wear, vibrations, and internal seal damage, fuel tanks can develop leaks. A supervisor asks his assembled D check crew, "Does anyone want to be a 'frogman'?" The joyless but necessary chore falls to John. Looking somewhat like a scuba diver without flippers, he dons special cotton coveralls, puts on a respirator connected to a fresh air supply, and takes tools, sealant, and a safety light with him. Through a small opening in the bottom of the wing, he squeezes his way into the defueled wing tank, locates the source of the fuel tank leak, and seals it.

Built into the wings of the plane, the fuel tanks of a 747 are a maze of walled compartments connected by small openings. Fuel tanks are no place for the claustrophobic. A 747-400 can hold more than 57,000 gallons of fuel. This fuel capacity makes it possible to fly extremely long routes nonstop, such as from San Francisco, California, U.S.A., to Sydney, Australia—a distance of 7,400 miles.

Three stories above the ground on the flight deck, an avionics technician inspects a built-in testpattern display on the TVlike weather radar indicator screen. Pilots use this instrument to detect and avoid thunderstorms and turbulence that may be as far as 300 miles ahead of the airplane. So when the pilot turns on the "Fasten Seat Belt" sign, he may have seen turbulence on his radar screen. However, to prevent injuries, many airlines request that when seated, passengers keep their seat belts fastened at all times, even if the captain turns off the sign. Atmospheric changes in the form of clear air turbulence are often encountered before pilots have time to turn it on.

During the D check, safety equipment, such as life vests and emergency lighting, is checked or replaced. When a check of the passenger emergency oxygen system is under way, oxygen masks dangle like oranges on branches. Jet airplanes routinely cruise at altitudes of four to seven miles above the earth, where the oxygen content and the atmospheric pressure are insufficient to sustain life. How is this problem solved? The aircraft's pressurization system draws in outside air and then compresses it. This air is finally supplied to the cabin at an acceptable temperature. If the air pressure in the cabin falls below safe levels, oxygen masks automatically drop from overhead compartments. The emergency oxygen is supplied to the passengers until the aircraft descends to an altitude where the emergency oxygen is no longer needed. On some airplanes, oxygen masks are stowed in passenger seatback compartments, not in overhead compartments. That is why it is important to pay attention to preflight passenger briefings, which identify the location of the oxygen masks.

A heavy maintenance check is also the time to install new cabin walls and ceiling panels as well as to replace carpets, curtains, and seat cushion covers. Galley equipment is disassembled, cleaned, and sanitized.

Ready to Fly

After 56 days of inspections, checks, repairs, and maintenance, the aircraft is ready to leave the hangar and resume flying passengers and cargo. Only a small fraction of the maintenance operations have been mentioned here. But before flying again, the aircraft may be test flown by a special crew to ensure that all systems function properly. It is reassuring to consider briefly how much expertise and technology go into keeping the aircraft that you fly in mechanically sound.

However, the best single tool in aircraft maintenance is said to be the human element —sharp eyes and alert minds. The trained personnel take their jobs very seriously. They know that poor maintenance can cause big problems. Their goal is to provide reliable aircraft that will speed you to your destination safely and comfortably.

Source:

http://www.aerosphere.com/html/747_d-inspection.html

(originally appeared in the September 8, 1999, edition of AWAKE! magazine)

Jumbo Jet Strip Down

BBC Two's Engineering Gaints programme features the enourmous work of a D-Check on British Airways' B747-400 G-CIVX.. :o

Aircraft maintenance checks

Aircraft maintenance checks are periodic inspections that have to be done on all commercial/civil aircraft after a certain amount of time or usage. Airlines and other commercial operators follow a continuous inspection program approved by the Federal Aviation Administration (FAA) in the United States or by other airworthiness authorities such as the European Aviation Safety Agency (EASA). The maintenance program includes both routine and detailed inspections. Airlines and airworthiness authorities casually refer to the detailed inspections as "checks", commonly one of the following: A-check, B-check, C-check or D-check. A- and B-checks are lighter while C- and D- are considered heavier checks.

The maintenance of aircraft is differentiated into line maintenance and overhaul (base maintenance). The work that has to be done in the short term is called line maintenance. This means that the aircraft keeps to its usual schedule. The daily, weekly and monthly checks are carried out overnight, the next morning the aircraft goes back into scheduled service. Merely the C-Check that is carried out about every one and a half years takes somewhat more than one day. For an overhaul, let it be an IL (intermediate layover check) or D-Check, the aircraft is taken out of service for several weeks.

Pre-flight Check / Trip Check:

The lowest-level maintenance event is the pre-flight check that precedes every flight and involves a visual inspection of the aircraft by the cockpit crew (and mechanics if present) at the gate. The aim of this check is to detect obvious external damage, wear and oil or hydraulic leaks. Depending on the aircraft type it lasts for 15 to 60 minutes.

Ramp-Check:

The next maintenance event in the hierarchy is the ramp check, in which mechanics test individual functions of the aircraft, check tire pressure and brakes and replenish fluids such as hydraulic, oil and water. A visual inspection of the aircraft is also carried out, both externally and in the cabin. Such a check, carried out on a daily basis, requires between 6 and 35 man-hours.

Next in size is the weekly service check, a combination of the work performed in the ramp check with tasks such as topping up the water, air and oil and thorough cleaning of the cabin, which takes between 10 to 55 man-hours.

A-check:

This is performed approximately every one to two months, after 300-600 flight hours or 200–300 cycles, depending on aircraft type. (Maintenance checks are the same for long haul and short haul aircraft because the maintenance schedule is based on airframe hours and landings (known as cycles). Aircraft flying several short trips a day may have maintenance due earlier than aircraft flying long-haul because they have more cycles attributed to them.)

As well as general inspections of the interior and the aircraft hull, it also covers service checks as well as engine and function checks. At the same time the technicians replenish consumables such as oil, water and air and eliminate defects whose rectification has been postponed on the grounds that they did not impair flight safety. If any extensive seat repairs are required, these are also carried out in this interval inspection. It needs about 20–60 man-hours and is usually performed overnight at an airport gate. The occurrence can be delayed by the airline if certain predetermined conditions are met.

Examples of A-check items include:

• General external visual inspection of aircraft structure for evidence of damage, deformation, corrosion, missing parts

• Check crew oxygen system pressure

• Operationally check emergency lights

• Lubricate nose gear retract actuator

• Check parking brake accumulator pressure

• Perform Built-in Test Equipment (BITE) test of Flap/Slat Electronics Unit

B-check:

Contemporary maintenance programs do not use this interval. The B-check, which comes into play only in some types of aircraft such as the Boeing 747-200 or the B737-200, corresponds to an enhanced A-Check with a slightly more detailed check of components and systems. Special equipment and tests may be required but it does not involve, however, detailed disassembly or removal of components. It needs about 120-150 man-hours, depending on the aircraft, and is usually completed within a day at an airport hangar. This kind of check is performed approximately every 5-8 months or after 1000 hours of flight time. A similar occurrence schedule applies to the B-check as to the A-check. However, B-checks may also be incorporated into successive A-checks, i.e.: Checks A-1 through A-10 complete all the B-check items.

HEAVY CHECKS

The following two checks are traditionally known as heavy checks. They are normally accomplished at the main maintenance base of the airline where specialized manpower, materials, tooling, and hangar facilities are available.

C-check:

|

| C-Check on Crystal Holidays' leased charter B737 |

This is an intensive review carried out approx. every 18–24 months or after about 5000 hours of flight time. The schedule of occurrence has many factors and components thus varies by aircraft category and type. It is a high-level check that involves extensive tooling, test equipment, and special skill levels. This maintenance check requires a large majority of the aircraft's components to be inspected therefore the aircraft will be partially disassembled in a hangar at a maintenance base. This entails thorough inspections inside and outside, along with meticulous examination of structures (load-bearing components on the fuselage and wings) and functions. The time needed to complete such a check is generally up to five days and the effort involved can require up to 1500 and 2000 man-hours.

The C-check includes the lower checks, i.e. A-, B-, and Daily checks.

Examples of C-check items:

• Visually check flight compartment escape ropes for condition and security

• Check operation of DC bus tie control unit

• Visually check the condition of entry door seals

• Operationally check flap asymmetry system

• Pressure decay check APU fuel line shroud

• Inspect engine inlet TAI ducting for cracks

• Operationally check RAT deployment and system

IL-Check (Intermediate Layover Check):

The classical IL-Check [or HMV (heavy maintenance visit)] is carried out every four to six years, about halfway between the D-Checks and lasts between 2 to 4 weeks. Recently lost its significance as the lifespan and reliability of the systems are continually improving. Therefore it is now possible to distribute the elements of the IL-Check over several C-Checks or to delay it to the next D-Check.

To obtain easier access to the fuselage and wing structure for inspection purposes, a number of large assemblies such as the high-lift devices are dismantled. At the same time numerous items of equipment and systems are tested and repaired as necessary. Cabin components such as seats, galleys and toilets are also completely overhauled and, if necessary, the aircraft will be repainted.

D-Check:

This check can also be referred to as Structural check which is due every 6 to 10 years or after about 25.000 hours of flight time.

|

| Completely empty cabin: wall and ceiling panels all removed |

During a D-check the entire structure is inspected down to the smallest detail. The engines, the landing gears and the high-lift devices are dismantled, along with the cabin interior and the wall and ceiling panels. The instruments, the electrical systems, the electronics, hydraulic and pneumatic equipment is also removed. All equipment dismantled and taken apart is closely scrutinized and any necessary repair work is carried out.

Every component is given a docket that states when and whereto it has to be delivered in a serviceable condition in order for the aircraft to be finished on time. Once the aircraft has been stripped to its skeleton, the outer skin with ten of thousands rivets and the load-bearing structure of the aircraft can be scrutinized for damage and corrosion. Here, non-destructive testing methods such as eddy-current, ultrasonic and x-raying are used to detect the tiniest hairline cracks in the aircraft structure or its retaining elements.

Given the time requirements of this check, many airlines use the

opportunity in order to also make major cabin modifications on the

aircraft, which would otherwise require an amount of time that would

have to put the aircraft out of service without the need for an

inspection. This may include new seats, entertainment system, carpeting,

etc.

Such a check can generally take up to 50.000 man-hours and 4-6 weeks to complete, depending on the aircraft and the number of technicians involved. It also requires the most space of all maintenance checks, and as such must be performed at a suitable maintenance base.

|

| Celebrating a succesful D-check on a B747 at HAITEC |

The requirements and the tremendous effort involved in this maintenance check make it by far the most expensive with a total cost up to 8 to 10 million dollars. Because of the nature and cost of such a check, most airlines — especially those with a large fleet — have to plan D-checks for their aircraft years in advance. Often older aircraft being phased out of a particular airline's fleet are either stored or scrapped upon reaching their next D-check due to the high costs involved in comparison to the aircraft's value. On average a commercial aircraft undergoes three D-checks before being retired.

The D-check includes the lower checks, i.e. A-, B-, C- and Daily checks.

Examples of D-check items include:

• Inspect stabilizer attach bolts

• Inspect floor beams

• Detailed inspection of wing box structure

Source:

http://en.wikipedia.org/wiki/Aircraft_maintenance_checks

http://www.lufthansa-technik.com/aircraft-maintenance

Monarch MRO

http://www.focus.de/reisen/flug/airline-sicherheit/tid-14743/flugzeugwartung-teure-checks-fuer-alte-kisten_aid_413162.html

http://www.aviationpros.com/article/10388655/whats-this-a-check-c-check-stuff

http://www.netairspace.com/forum/

https://www.eurocontrol.int

[Jobs at close from Malpensa] Maintenance Supervisor

Maintaining an aircraft and ensuring that it is constantly airworthy. Airplanes have to be in perfect shape so we need technicians who are always prepared, skilled and up-to-date in order to operate both routine and extraordinary maintenance. You have to keep studying but you won’t get bored...

Line maintenance Swiss-módra

Állóhelyen végrehajtott rutinellenőrzések a Swiss International Air Lines HB-JHC lajstromjelű A330-asán..

Multi-modal Digital Avionics for Commercial Applications

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iS1ozdWo2T1pmbFU/view?usp=sharing

Avionics bay vulnerability?

As the aviation industry secures itself by ensuring passenger personal electronic devices are charged and rerouting flights around war zones, a vulnerability lurks just beneath the carpet of the venerable Boeing 777, and has attracted attention on aviation forums and social media.

In the forward galley area near the L1 door and flight deck, a small access panel sits below the carpet which acts as the gateway to the 777’s electronics and engineering bay. The bay, referred to as the ‘E/E bay’, contains many of the 777’s extremely sensitive systems. A recently posted YouTube video, below, shows how shockingly easy it is to access the E/E bay, and how seemingly little has been done to keep people out.

The systems in the E/E bay vary from fuse panels to the Airplane Information Management System (AIMS), also known as “the brains” of the aircraft. AIMS provides flight and maintenance crews all pertinent information concerning the overall condition of the airplane, its maintenance requirements and its key operating functions, including flight, thrust and communications management, according to Boeing’s description. Also in the E/E bay are several tanks containing oxygen connected to the flight crews’ masks.

Needless to say, any flight would be extremely vulnerable if a passenger were to access this bay in-flight. The vulnerability seems to exist on some Boeing 777s, 767s and 747s, as other models (including those manufactured by Airbus) have either a locked access panel, or the panel is located inside the flight deck.

A late 2013 post on pprune.org (Professional Pilots Rumor Network) notes that the E/E hatch on the Boeing 787 requires a special tool to open, but that this security feature had not trickled down to the 777 at that time. Additionally, it noted that some airlines have bolted the E/E hatch shut not because of security concerns, but due to incidents where employees would fall down the hatch when someone else was inside doing maintenance. Indeed, Boeing published this article on how crew can avoid falls through proper and consistent use of hatch barriers.

Earlier this month the popular Crikey blog suggested that the technical media “has been at pains not to discuss” an alternative access route to the cockpit for years. But Air New Zealand confirmed the security flaw in the 777, said Crikey, after news surfaced that one of its captains locked a co-pilot out of the cockpit for several minutes. A 2012 video about the 777 E/E bay notes that the breakers for the flight deck door locking system are located in the E/E bay.

Whether a lack of directive to secure the E/E bay from passenger access may be due to cost or lack of concern, it seems odd that such a public vulnerability is allowed to exist on such a popular aircraft. Will industry address this issue now?

Boeing declined to comment. The FAA did not comment.

This video shows a tour of a Boeing 777’s avionics bay. It’s particularly fascinating in that it shows how you can descend from the main cabin to the lower level through a hatch, and from there make your way to the forward cargo hold or to the outside, through a hatch close to the nose landing gear...

This is a similar video for the Airbus A330 where they actually walk from the avionics bay to the forward cargo hold...

Source:

https://aviationnotes.wordpress.com/2014/11/

https://www.runwaygirlnetwork.com/2014/07/22/will-industry-address-vulnerability-beneath-the-carpet-of-the-777/

AF 358 - final report

Download it:

https://drive.google.com/file/d/0B8aiechh7K6iTndWdXhsTjNMQmc/view?usp=sharing

AF 358 aka the "Toronto Miracle"

|

| Completely burnt out - photo taken the other day |

Air France Flight 358 was an Airbus A340-313E, registration F-GLZQ, on a scheduled international flight from Paris, France, to Toronto, Ontario, Canada. On August 2, 2005, just after landing at Toronto Pearson International Airport at 4:01 p.m. EDT, it crashed into nearby Etobicoke Creek, approximately 300 m beyond the end of the runway. All 309 passengers and crew aboard the Airbus A340 survived, with 12 people sustaining serious injuries. The accident highlighted the role played by highly trained flight attendants during an emergency.

Aircraft

The aircraft operating Flight 358 was a 295-seat Airbus A340-313E powered by four CFM International CFM56 engines. With manufacturer's serial number 289 and registration F-GLZQ, it was first flown on August 3, 1999, and delivered to Air France on September 7, 1999. There were 297 passengers and 12 crew aboard the Airbus. On this flight, it was flown by Captain Alain Rosaye, 57, and First

Officer Frédéric Naud, 43. Rosaye was a seasoned pilot with 15,411 total

flight hours and Naud had 4,834 hours of flight time.

Passengers

Out of the 297 passengers, there were 168 adult males, 118 adult females, 8 children and 3 infants. Among them, 3 supplemental cabin crew members were seated in crew seats, one of them in the third occupant seat of the flight deck and two in the flight crew rest area. The passengers consisted of businesspersons, vacationers and students.

Incident

The accident occurred on August 2, 2005 at 16:03 EDT. Air France Flight 358, an Airbus A340-313E with 297 passengers and 12 crew, overshot the end of runway 24L at Toronto Pearson International Airport and came to rest in a small ravine 300 m past the end of the runway. All passengers and crew evacuated the aircraft successfully. Twelve major injuries and no fatalities resulted from the accident. The rest suffered minor or no injuries. A post-crash fire destroyed the aircraft.

The flight landed during exceptionally bad weather – severe winds, heavy rain, and localized thunderstorms near the airport – and touched down further along the runway than usual. Some passengers report that the plane was rocking from side to side before landing, possibly due to turbulence and gusting winds associated with the storm systems.

The plane was cleared to land at 16:04 EDT on Runway 24L, which, at 2,700 m in length, is the shortest runway at Pearson Airport. After touchdown, the aircraft did not stop before the end of the runway, but continued for 300 meters until it slid into the Etobicoke Creek ravine with a speed of 148 km/h, on the western edge of the airport near the interchange of Dixie Road and Highway 401.

|

| Passenger photo taken during the evacuation |

After coming to rest, fire was noticed outside the aircraft, and an evacuation order was given. The two rear left exits remained closed due to the fire. On opening the emergency exits, one of the right middle exit slides (R3) deflated after being punctured by debris from the aircraft, while one of the left slides (L2) failed to deploy at all. A number of passengers were forced to jump from the aircraft to exit. The actions of the flight attendants ensured that all of the passengers were evacuated within the required 90 second time frame.

Emergency response teams responded to the incident and were on site within 52 seconds of the crash occurring.

After the crash, some passengers - including those who were injured - scrambled up the ravine to Highway 401 which runs almost parallel to the runway. Peel Regional Police located the first officer and several passengers along Highway 401, receiving assistance from motorists who were passing the airport when the crash occurred. Some motorists took injured people, including the pilot, directly to hospitals. Other motorists took non-injured passengers to the airport. The main fire burned for two hours, ending just before 18:00 EDT. All fires were out by early afternoon on 3 August 2005, and investigators were able to begin their work.

The accident caused the cancellation or diversion of hundreds of flights, with ripple effects throughout the North American air traffic system. By that night, four of the five runway surfaces at Pearson were back in service, but the flight and passenger backlog continued through the next day.

This was the first time an Airbus A340 series was involved in a crash, ending its 14-year clean record. The aircraft involved entered service in 1999 and had its last maintenance check in France on 5 July 2005. It made 3,711 flights for a total of 28,426 flight hours.

Weather

A METAR for Pearson was released almost exactly at the time of the accident. It stated that the weather at 16:04 EDT consisted of winds from 340° true at 24 kn gusting to 33 kn, with 1 1⁄4 miles visibility in heavy thunderstorms and rain. The ceiling was overcast at 4,500 feet above ground level with towering cumulus clouds. The temperature was 23 °C. According to the Canada Air Pilot, runway 24L has a heading of 227° true (237° magnetic), and the minima for the ILS approach are ceiling 200 feet above ground level and visibility 1⁄2 mile or runway visual range (RVR) of 2600.

The Canadian Broadcasting Corporation reported that the crash occurred two hours after a ground stop was declared at the airport because of severe thunderstorms in the area ("red alert" status, which, for safety reasons, halts all ground activity on the apron and gate area. Aircraft can still land, and take off if still in queue). Visibility at the time of the accident was reported to be very poor. There was lightning, strong gusty winds, and hail at the time and the rain just began as the plane was landing. Within two hours the winds increased from 5 to 30 km/h and the temperature dropped from 30 to 23 °C. A severe thunderstorm warning was in effect since 11:30 a.m. and all outbound flights and ground servicing operations had been canceled but landings were still permitted.

Injuries

Out of the twelve passengers who suffered major injuries, nine suffered the injuries from the impact and three suffered the injuries from the evacuation. Most of the injuries occurred to passengers and crew located in the flight deck and forward cabin.

According to passenger reports, the leap from the aircraft to the ground caused many of the injuries, including broken legs, and ruptured vertebrae. The Captain sustained back and head injuries during the impact of the crash when his seat was wrenched out of place by the force of the impact, causing him to hit his head against the overhead controls. Minor injuries included twisted ankles, sore necks, bruises and effects from smoke inhalation. A total of 33 persons were taken to various hospitals within and outside Toronto for treatment, of which 21 were treated for minor injuries and released.

Investigation

Evidence

|

| Too far down the runway... |

The flight data recorder and cockpit voice recorder were sent to France for analysis. Preliminary results indicate that the plane landed 1,220 m from the start of the 2,743 m runway (much further along than normal) at a ground speed of 148 knots – 140 knots being considered normal – with a tailwind, skidded down the runway and was traveling over 70 knots as it overran the tarmac and fell into the ravine. Tire marks extend 490 m indicating emergency braking action.

Réal Levasseur Shedalin, the TSB's lead investigator for the accident, said the plane landed too far down the runway to have been able to stop properly on such wet pavement. Investigators have found no evidence of engine trouble, brake failure, or problems with the spoilers or thrust reversers.

Ireggularities

The final report of the TSB investigation states: "During the flare, the aircraft travelled through an area of heavy rain, and visual contact with the runway environment was significantly reduced." This suggests the possibility that the plane was hit in heavy weather by a wet downburst, causing the Airbus to land long. Based on the Air France A340-313 Quick Reference Handbook (QRH), page 34G, "Landing Distance Without Autobrake", the minimum distance of 1,155 m would be used in dry conditions to bring the aircraft to a complete stop. In wet conditions the braking distance increases with a 5-knot tailwind, reversers operative, and a 6.3 mm of downpour on the runway to 2,016 m. This runway length was obviously not available at touch down of AF 358.

Conclusions

The TSB concluded in their final report that the pilots had missed cues that would have prompted them to review their decision to land. In their report the TSB cited that

- Air France had no procedures related to distance required from thunderstorms during approaches and landings.

- After the autopilot had been disengaged, the pilot flying increased engine thrust in reaction to a decrease in airspeed and a perception that the aircraft was sinking (spatial disorientation). The power increase contributed to an increase in aircraft energy and the aircraft deviated above the flight path.

- At 300 feet above ground level, the wind changed from a headwind to a tailwind.

- While approaching the threshold, the aircraft entered an intense downpour and the forward visibility became severely reduced.

- When the aircraft was near the threshold, the crew members committed to the landing and believed their go-around option no longer existed.

- The pilot not flying did not make the standard callouts concerning the spoilers and thrust reversers during the landing roll. This contributed to the delay in the pilot flying selecting the thrust reversers.

- There were no landing distances indicated on the operational flight plan for a contaminated runway condition at the Toronto / Lester B. Pearson International Airport.

- The crew did not calculate the landing distance required for runway 24L despite aviation routine weather reports (METARs) calling for thunderstorms. The crew were not aware of the margin of error.

- The topography at the end of the runway beyond the area and the end of Runway 24L contributed to aircraft damage and injuries to crew and passengers.

The TSB advised changes to bring Canadian runway standards in line with those used abroad, either by extending them to have a 300 m runway safety area (or Runway End Safety Area) or, where that is impossible, providing an equivalently effective backup method of stopping aircraft. Other recommendations that the TSB made includes having the Department of Transport establish clear standards limiting approaches and landings in convective weather for all operators at Canadian airports, and mandate training for all pilots involved in Canadian air operations to better enable them to make landing decisions in bad weather.

Compensation

Within one week of the crash, cash payments ranging from C$1,000 to C$3,700 were given to passengers for interim emergency use. These funds were given to passengers through an emergency centre set up near the airport. These payments were independent of the claims process, which has been started for passengers who have not retained counsel. It is expected that the insurers of Air France will pay for all damages as well as extra compensation for having passengers go through the ordeal; however, only amounts of €6,000 to €9,000 have been offered, prompting passengers to turn to the lawsuit to seek legal action. All passengers have also been offered a free round-trip ticket to any Air France destination in the world in the same fare class in which they were originally booked on AF358.

After a lawsuit lasting four and a half years, Air France settled the compensation lawsuit with 184 of the 297 passengers (no crew members included) aboard Flight 358. The compensation is for a total of $12 million. Air France will pay $10 million, and have been released from passengers' claims stemming from the incident, according to the judgment's summary. Airbus and Goodrich, the company that made the emergency evacuation system on the plane will pay $1.65 million, and claims against them in a lawsuit have been released.

Litigation

Passenger class action

Within a few days after the accident, a class action suit was filed on behalf of all passengers on board by representative plaintiff Suzanne Deak to the Ontario Superior Court of Justice. The attorneys representing Deak and the passengers are Gary R. Will and Paul Miller from Will Barristers in Toronto. The plaintiffs sought payments for general and aggravated damages in the amount of $75 million, and payments for special damages and pecuniary damages in the amount of $250 million. A second class action lawsuit was also filed by plaintiffs Sahar Alqudsi and Younis Qawasmi (her husband) for $150 million a few days later. However, both suits had since merged as only one lawsuit was allowed to proceed to court.

In December 2009, a $12 million settlement agreement was reached between Air France and the class. The settlement resolved the claims of 184 passengers and their families. Forty-five other passengers had opted out of the suit, while 68 others have already agreed to a settlement with Air France.

Air France stated that it would not lose any money from the lawsuits as it is covered by its insurers. Air France did not provide further contacts and assistance to those who retained counsel of the lawsuit until an agreement has been made between both sides' lawyers.

Air France lawsuit

|

| R(E)SA could have prevented this to happen..? |

In June 2008, almost 3 years after the accident, Air France filed a lawsuit against the Greater Toronto Airports Authority, NAV Canada, and the Government of Canada for $180 million. In the statement of claim filed with the Ontario Superior Court of Justice, Air France alleged that the "GTAA failed to provide a safe environment for the conduct of civil air operations." The statement also claims that "The overrun and the consequent injuries to persons and damage to property were caused solely by the negligence of the defendants". Air France says Transport Canada was "negligent" by not implementing the recommendations of a coroner's inquest into the 1978 crash (Air Canada Flight 189) that urged the creation of a 300-metre safety area to give aircraft more room to stop after landing.

Aftermath

An inquiry by the Transportation Safety Board of Canada found runway safety zones at the end of runways at some Canadian airports are below accepted international standards. The report highlighted that Toronto Pearson's runways meet current Canadian standards, and that runway 24L has a de facto 150 metre RESA. The TSB also suggested precautions are needed to be taken by airlines when landing in bad weather.

Flight 358 is no longer used on this route (number is now used for Air France flights from Roland Garros Airport in Sainte-Marie, Réunion to Paris). The flight route designation for Air France's Paris-Toronto route is now Flight 356, using a Boeing 777 aircraft.

Source:

https://en.wikipedia.org/wiki/Air_France_Flight_358

Feliratkozás:

Bejegyzések (Atom)